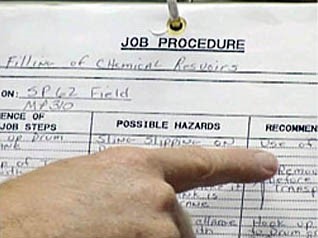

A Job Hazard Analysis (JHA) is the breaking down of a job into its component steps and then evaluating each step, looking for hazards. Each hazard is then corrected or a method of worker protection (safe practice or PPE) is identified. Additional requirements for worker training, certification, authorization, etc., may also be identified for the process or job. The final product is a written document….a standard of safe operation for a particular job. A Job Hazard Analysis is one component of the university’s commitment to employee safety and health.

Useful Links

The many benefits of Job Hazard Analysis include:

- Set performance standards

- Standardize operations based on acceptable safe practices and Personal Protective Equipment (PPE)

- Provides a form of training documentation regarding the employee’s knowledge of the job requirements

- Comply with Cal/OSHA requirements

- Reduces injuries

- Reduces absenteeism

- Increases productivity

- Increases morale

- Protects employees

- Assists in standard-specific compliance (e.g., personal protective equipment [PPE], Hazard Communication, etc…..)

Managers, Supervisors, and Principal Investigators are responsible for the development of JHA’s within their work areas. They can use the findings of a job hazard analysis to eliminate and prevent hazards in their workplaces. This is likely to result in fewer worker injuries and illnesses; safer, more effective work methods; reduced workers’ compensation costs; and increased worker productivity. The analysis also can be a valuable tool for training new employees in the steps required to perform their jobs safely. For a job hazard analysis to be effective, management must demonstrate its commitment to safety and health and follow through to correct any uncontrolled hazards identified.

A job hazard analysis can be conducted on many jobs in your workplace. Priority should go to the following types of jobs:

- Jobs with the highest injury or illness rates;

- Jobs with the potential to cause severe or disabling injuries or illness, even if there is no history of previous accidents;

- Jobs in which one simple human error could lead to a severe accident or injury;

- Jobs that are new to your operation or have undergone changes in processes and procedures; and

- Jobs complex enough to require written instructions.

Periodically reviewing your job hazard analysis ensures that it remains current and continues to help reduce workplace accidents and injuries. Even if the job has not changed, it is possible that during the review process you will identify hazards that were not identified in the initial analysis. It is particularly important to review your job hazard analysis if an illness or injury occurs on a specific job. Based on the circumstances, you may determine that you need to change the job procedure to prevent similar incidents in the future. If an employee’s failure to follow proper job procedures results in a “close call,” discuss the situation with all employees who perform the job and remind them of proper procedures. Any time you revise a job hazard analysis, it is important to train all employees affected by the changes in the new job methods, procedures, or protective measures adopted.

Departments may contact the EH&S Industrial Safety Program at ehs-industrialsafety@ucsb.edu for guidance in developing or reviewing their job hazard analysis documents. We can also assist you with hazard recognition, recommendation of control measures, and documentation of your findings. Please see the attached “Sample” JHA and JHA Template documents for initial guidance in preparing JHA’s for your department or work area.